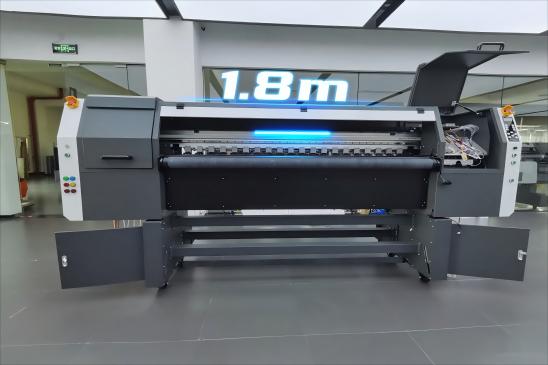

1.8m sublimation printer HYL-GT1804I

- Product Item : HYL-GT1804I

- Category: Textile printer

- Print Head: 4&8 EPSON I3200A1

- Print width:1800mm

- Ink: sublimation ink

- Max resolution: 3200DPI

Hyancolor HYL-GT1804I

1.8m Sublimation Printer with 4 i3200 Heads

Professional large-format sublimation printer designed for high-volume production with exceptional print quality. Equipped with 4 Epson i3200 heads, this 1.8m wide printer delivers outstanding performance for various sublimation applications.

Parameters

Maximum print width

1.8M

Number of printhead

4

Printing color

CMYK 4color/CMYK Lm Lc 6color

Compatible ink

Sublimation

Sublimation

Sublimation paper

Medium transmission

Auto media take - up system

Operation system

Win7、Win10 64位

RIP Software

MainTop/PhotoPrint/Hosonsoft

Interface

Reticle

Power requirements

AC220V 50/60HZ 3000W

Working environment

Temperature: 15 - 30℃ Relative Humidity: 40 - 65%

Packing Details

Printer Size:(L*W*H)

3420*1270*1580MM

Intergrated packing size

3.65*1.05*1.75MM

Split packingsize

4.05*0.85*1.25MM

N.W.

520KG

G.W.

650KG

20GP Container

20GP can load 6 pcs

40HQ

40HQ can load 12 pcs

Core Technology

| Maximum print width | 1.8M |

|---|---|

| Number of printhead | 4 |

| Printing color | CMYK 4color/CMYK Lm Lc 6color |

| Compatible ink | Sublimation |

| Sublimation | Sublimation paper |

| Medium transmission | Auto media take - up system |

| Operation system | Win7、Win10 64位 |

| RIP Software | MainTop/PhotoPrint/Hosonsoft |

| Interface | Reticle |

| Power requirements | AC220V 50/60HZ 3000W |

| Working environment | Temperature: 15 - 30℃ Relative Humidity: 40 - 65% |

| Printer Size:(L*W*H) | 3420*1270*1580MM |

|---|---|

| Intergrated packing size | 3.65*1.05*1.75MM |

| Split packingsize | 4.05*0.85*1.25MM |

| N.W. | 520KG |

| G.W. | 650KG |

| 20GP Container | 20GP can load 6 pcs |

| 40HQ | 40HQ can load 12 pcs |

Printhead System

Equipped with 4 Epson i3200-A1/i1600-A1 print heads, the printer delivers exceptional print quality and speed. The advanced micro-piezo technology ensures precise ink droplet control, resulting in vibrant colors, sharp details, and consistent performance even during long production runs.

1.8m Print Width

The 1.8-meter wide printing area allows for large format production, increasing efficiency for big projects. This width is ideal for various applications including textiles, home decor, and promotional materials.

Capping Station System

Equipped with a high-performance capping station system, the printer ensures reliable protection and maintenance of print heads during standby or non-operational periods. The system features precision-engineered rubber caps that form an airtight seal over the print head nozzles, effectively preventing ink from drying out, clogging, or being contaminated by dust and debris

Big Functional Control Panel

Featuring a large, intuitive control panel with a high-resolution touchscreen display, this printer simplifies operation and monitoring of all key functions. The user-friendly interface presents critical production metrics—such as print speed, ink levels, job progress, and system status—at a glance, while customizable shortcut buttons allow quick access to frequently used settings like material type, print modes, and maintenance functions.

Double heat dryer system

Equipped with a dual-stage heat drying system, this printer ensures rapid and thorough ink curing for various substrates. The first stage utilizes controlled infrared heating to penetrate and pre-dry the ink, while the second stage employs high-velocity hot air circulation to finalize the drying process—working in tandem to achieve complete ink solidification in a fraction of the time required by single-dryer setups

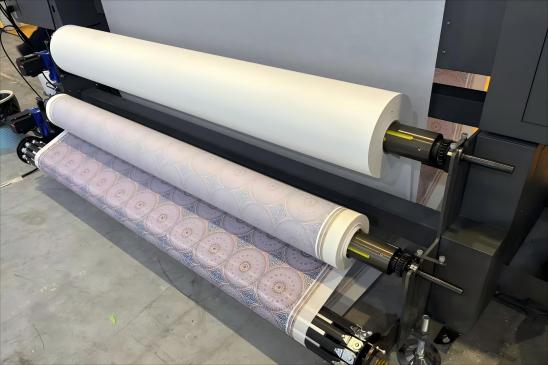

Jumbo roll media loading

The advanced smart feeding system ensures precise media handling, reducing paper jams and misalignment. It automatically adjusts tension and speed according to media type, ensuring smooth operation and consistent print results across different materials and thicknesses.

Applications

Textile Printing

Home Decor

Sportswear

Promotional Products

Flag Printing

Soft Signage